Metallic wire for flat card

Metallic wire for flat card

The application for metallic card clothing onto spinning carding machines has no limits and is used in the production of low, medium and high quality yarns.

Since there are numerous solutions available for flat cotton cards we always ask our customers for the following information in order to accurately determine the type of card clothing to use:

- material to be processed;

- microns;

- type and staple length in mm of fibers;

- deniers.

And technical data concerning the machinery:

- type of machine and brand name;

- working width;

- diameter of rollers;

- production in kilos per hour;

- speed of cylinder/doffer;

- number of flat tops.

Once supplied with this information we can suggest the best combination of metallic wire for any type of fibers to be processed, thanks to the research and experience we have acquired in carding over the years.

Card clothing specifications

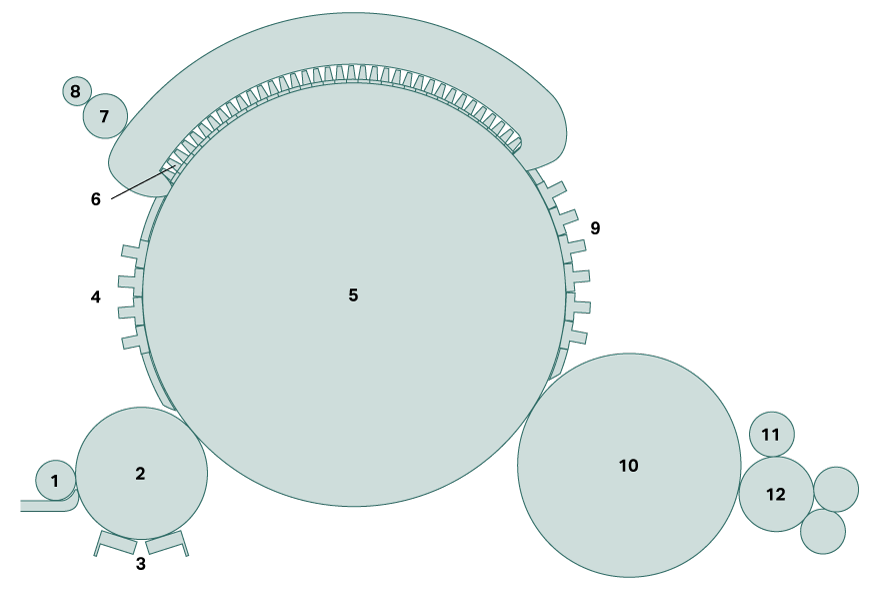

1 FEED ROLLER

2 LICKERIN (SINGLE OR TRIPLE LICKERIN CARDS)

3 LICKERIN SEGMENTS

4 PRE-CARDING ABOVE LICKERIN

5 CYLINDER

6 REVOLVING FLAT TOPS

7 FLAT CLEANING ROLLERS

8 FLAT CLEANING ROLLERS

9 FRONT CARDING ABOVE DOFFER

10 DOFFER

11 CLEANING ROLLER

12 STRIPPING ROLLER

Cylinder wire selection

| CODE | TECHNICAL SPECS | PPSI |

|---|---|---|

| CYL 1080 | 0.4 x 2.0 x 30°/35° | 1080 |

| CYL 960 | 0.4 x 2.0 x 30°/40° | 960 |

| CYL 860 | 0.5 x 2.0 x 30° | 860 |

| CYL 860 | 0.5 x 2.5 x 25°/30° | 860 |

| CYL 720 | 0.6 x 2.0 x 20°/30° | 720 |

| CYL 720 | 0.6 x 2.5 x 20°/30° | 720 |

| CYL 620 | 0.7 x 2.5 x 15°/30° | 620 |

| CYL 620 | 0.8 x 2.8 x 15°/25° | 620 |

| CYL 540 | 0.8 x 2.5 x 15° | 540 |

| CYL 540 | 0.8 x 2.8 x 15° | 540 |

| CYL 440 | 0.8 x 2.8 x 15° | 440 |

| CYL 400 | 0.9 x 3.2 x 15° | 400 |

All cylinders are available with special steel alloy “LL” Long Life for high production cards.

Universal doffer wire selection

| CODE | TECHNICAL SPECS | PPSI |

|---|---|---|

| DOF 340 | 0.9 x 4.0 x 25°/30° | 340 |

| DOF 360 | 0.9 x 4.0 x 25°/30° | 360 |

| DOF 385 | 0.9 x 4.0 x 25°/30° | 385 |

| DOF 400 | 0.9 x 4.0 x 25°/30° | 400 |

| DOF 350 | 0.9 x 5.0 x 25°/30° | 350 |

All doffers are available as Striaton (R) and Banana Shape (BAN).

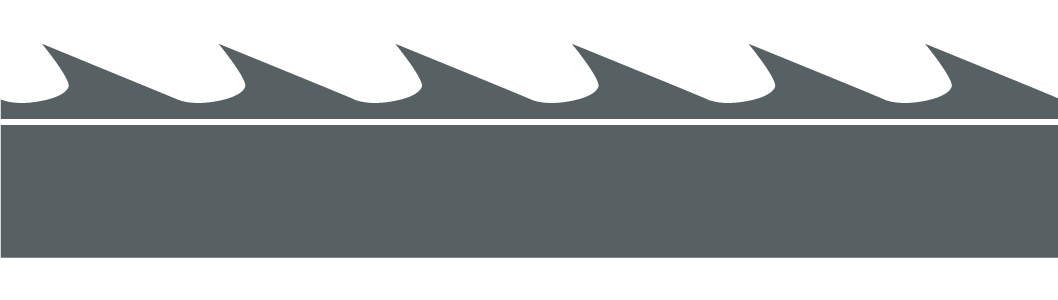

REGULAR

BAN

R

R-BAN

Lickerin wire selection

| CODE | ANGLE | H 5.5 x PPI |

|---|---|---|

| LK | 10°/5° | 4 to 5.5 |

| LK | 0°/-5° | 4 to 5.5 |

Standard grooved lickerin.

Wire base to be confirmed and checked.

Rib thickness available from 1.0 to 1.4 mm.

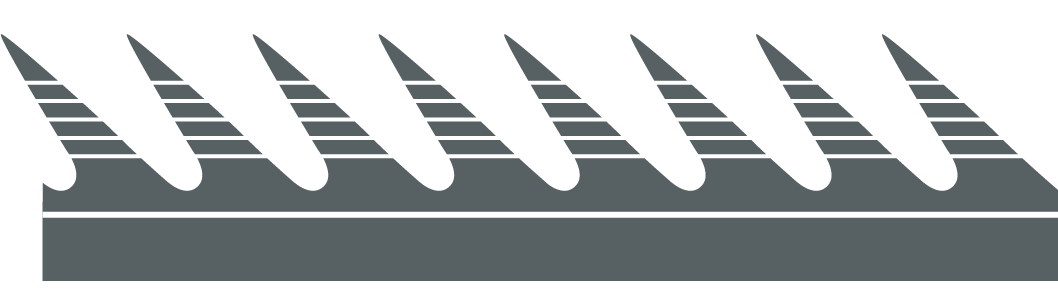

Interlocking lickerin wire selection

| CODE | ANGLE | H 5.0 x PPSI |

|---|---|---|

| V 8 | 10° | 44 |

| V 8 | 5° | 35 to 44 |

| V 8 | 0° | 24 to 35 |

| V 12 | 10° | 60 to 90 |

| V 12 | 5° | 60 to 90 |

| V 16 | 20° | 160 to 210 |

| V 20 | 20° | 210 to 240 |

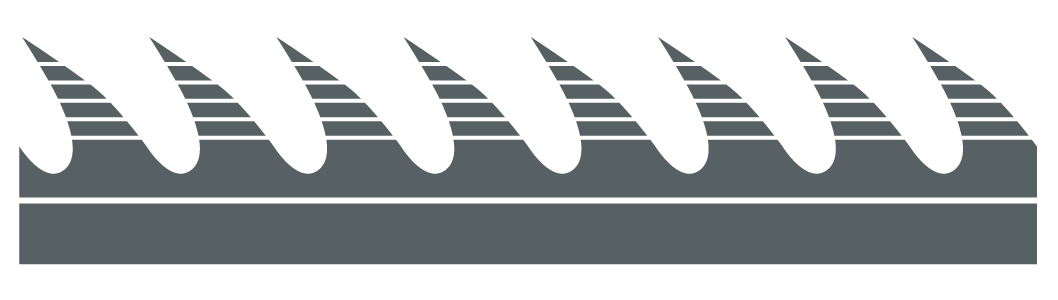

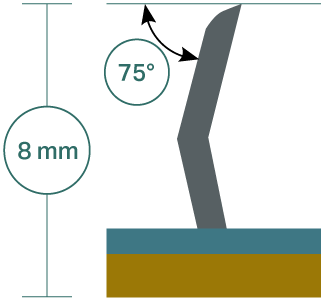

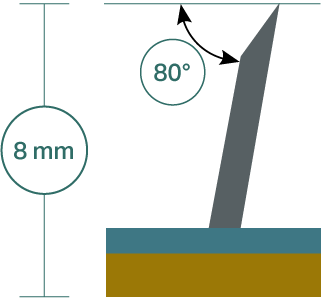

Revolving flat tops

type A

type B

| CODE | TYPE | PPSI | USE |

|---|---|---|---|

| FT 270 | B – FLAT WIRE 80° | 270 | POLYESTER FIBERS > 3.0 DTEX |

| FT 330 | B – FLAT WIRE 80° | 330 | POLYESTER FIBERS 1.0 to 3.0 DTEX |

| FT 350 | A – BICONVEX WIRE 75° | 350 | POLYESTER / BLENDS |

| FT 380 | A – BICONVEX WIRE 75° | 380 | POLYESTER / BLENDS |

| FT 400 | A – BICONVEX WIRE 75° | 400 | OE / POLYESTER / BLENDS |

| FT 420 | A – BICONVEX WIRE 75° | 420 | OE / RING SPUN |

| FT 450 | A – BICONVEX WIRE 75° | 450 | OE / RING SPUN / COMBED |

| FT 480 | A – BICONVEX WIRE 75° | 480 | RING SPUN / COMBED |

| FT 500 | A – BICONVEX WIRE 75° | 500 | COMBED COTTON |

| FT 520 | A – BICONVEX WIRE 75° | 520 | COMBED COTTON |

flat tops available with progressive setting (PRG)

| CODE | TYPE | PPSI | USE |

|---|---|---|---|

| FT 33/44 prg | A – BICONVEX WIRE 72° | 330-440 | BLENDS / OE / RING SPUN |

| FT 38/52 prg | A – BICONVEX WIRE 72° | 380-520 | OE / RING SPUN / COMBED |

| FT 38/55 prg | A – BICONVEX WIRE 75° | 380-550 | RING SPUN / COMBED COTTON |

| FT 42/60 prg | A – BICONVEX WIRE 75° | 430-600 | FINE COMBED COTTON |

Stationary flat wire

type A

SCREW TYPE h 11 mm

type B

SCREW TYPE h 16.8 mm

type C

CLIPSED TYPE h 7.0 mm

type D

UNDER LICKERIN h 7.5 mm

| CODE | TYPE | PPSI | POSITION |

|---|---|---|---|

| FFT 65 | D | 65 | LICKERIN SEGMENT |

| FFT 85 | D | 85 | LICKERIN SEGMENT |

| FFT 100 | A/B/C | 100 | PRE-CARDING ABOVE LICKERIN |

| FFT 150 | A/B/C | 150 | PRE-CARDING ABOVE LICKERIN |

| FFT 250 | A/B/C | 250 | PRE-CARDING ABOVE LICKERIN |

| FFT 350 | A/B/C | 350 | PRE-CARDING ABOVE LICKERIN |

| FFT 250 | A/B/C | 250 | FRONT CARDING ABOVE DOFFER |

| FFT 350 | A/B/C | 350 | FRONT CARDING ABOVE DOFFER |

| FFT 450 | A/B/C | 450 | FRONT CARDING ABOVE DOFFER |

| FFT 550 | A/B/C | 550 | FRONT CARDING ABOVE DOFFER |

| FFT 650 | A/B/C | 650 | FRONT CARDING ABOVE DOFFER |

Metallic wire selection

cotton

| P < 15 Kg/h | open end | ring spun | combed |

|---|---|---|---|

| cylinder | cyl 720 | cyl 720 | cyl 860 |

| doffer | dof 360 b | dof 360 b | dof 385 b |

| lickerin | lk 10° – v8 10° | lk 10° – v8 10° | lk 10° – v8 10° |

| flat tops | ft 400 – ft 420 | ft 420 – ft 450 | ft 450 – ft 38/52 prg |

| 15 < p < 40 kg/h | open end | ring spun | combed |

|---|---|---|---|

| cylinder | cyl 720/860 | cyl 720/860 | cyl 960 |

| doffer | dof 360 b | dof 360 b | dof 360 b/385 b |

| lickerin | lk 10° – v8 10° | lk 10° – v8 10° | lk 10° – v8 10° |

| flat tops | ft 420 – ft 33/44 prg | ft 33/44 – ft 38/52 prg | ft 38/52 prg |

| p > 40 kg/h | open end | ring spun | combed |

|---|---|---|---|

| cylinder | cyl 860/960 | cyl 860/960 | cyl 960/1080 |

| doffer | dof 360 b | dof 360 b/385 b | dof 385 b/400 b |

| lickerin | lk 10° – v8 – v12 – v16 | lk 10° – v8 – v12 – v16 | lk 10° – v8 – v12 – v16 |

| flat tops | ft 450 – ft 38/55 prg | ft 480 – ft 38/52 prg | ft 38/52 prg – ft 38/55 prg |

synthetic fibers

| 1.0 < dtex < 1.8 | p < 15 kg/h | 15 < p < 40 kg/h | p > 40 kg/h |

|---|---|---|---|

| cylinder | cyl 620 | cyl 720 | cyl 860 |

| doffer | dof 340 R:B | dof 360 R:B | dof 360 R:B |

| lickerin | lk 5° – v8 – V12 | lk 5° – v8 – V12 | lk 5° – v8 – V12 |

| flat tops | ft 330 | ft 350 | ft 380 |

| dtex > 1.8 | p < 15 kg/h | 15 < p < 40 kg/h | p > 40 kg/h |

|---|---|---|---|

| cylinder | cyl 400 | cyl 440 | cyl 540 |

| doffer | dof 340 R:B | dof 340 R:B | dof 360 R:B |

| lickerin | lk 0° – v8 0° | lk0° – v8 0° | lk 0° – v8 0° |

| flat tops | ft 270 | ft 270 – ft 330 | ft 330 |

blends

| p < 15 kg/h | 15 < p < 40 kg/h | p > 40 kg/h | |

|---|---|---|---|

| cylinder | cyl 720 | cyl 720 | cyl 860 |

| doffer | dof 340 R:B | dof 360 R:B | dof 360 R:B |

| lickerin | lk 5° – v8 5° | lk 5° – v8 5° | lk 5° – v8 5° |

| flat tops | ft 350 – ft 380 | ft 380 – ft 400 | ft 400 – ft 33/44 prg |