Raising fillet

Raising fillet

Raising fillets continue to be increasingly important in finishing.

The right fillet will allow the customer to obtain improved results in the raising while at the same time decrease the number of passes required, thus increasing production.

To determine the exact raising fillet to be used it is necessary to know the material processed, the type and weight of the fabric that is to be worked on the raising machine.

The type of machine, the working width and the number of rollers (pile/counter) will determine the quantity necessary.

The choice of foundation and steel wire used is fundamental in the raising fillets. Tinned or stainless (inox) wire is used with wet fibers.

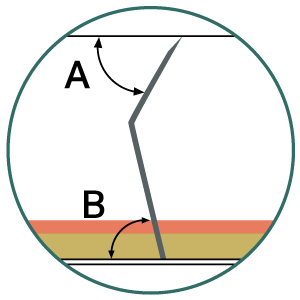

The angle, the treatment of the points, the grinding and polishing, and extra hardened points will give the raising fillet its final structure.

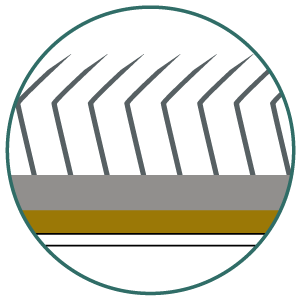

Foundations

raising fillet

RED RUBBER

3 – 4 – 5 PLY + PLY BACK

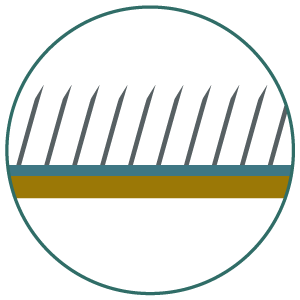

FELT

4 – 5 PLY + PLY BACK

auxiliary raising fillet

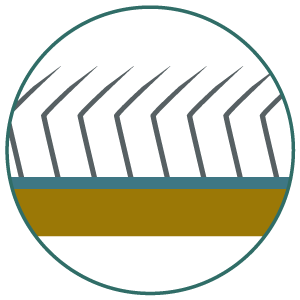

VULC

3 – 4 – 5 PLY + PLY BACK

4 – 5 PLY + FELT

VULC

3 – 4 – 5 PLY + PLY BACK

Angles

Wool fabrics

| width (mm) | foundation | wire | diameter (mm) | rows | ppsi | total h (mm) | angleS a – B |

|---|---|---|---|---|---|---|---|

| 23 | 4 RR | 25/29 bC | 0.530/0.380 | 12 | 100 | 10.5 | 40° – 82° |

| 23 | 3 RR | 26/30 bc | 0.480/0.355 | 12 | 130 | 10.0 | 40° – 82° |

| 23 | 3 RR | 27/31 bc | 0.430/0.330 | 12 | 145 | 10.0 | 45° – 76° |

| 23 | 3 RR | 28/32 bc | 0.405/0.305 | 12 | 150 | 10.0 | 45° – 76° |

| 23 | 3 RR | 29/33 bc | 0.380/0.280 | 12 | 155 | 10.0 | 45° – 76° |

| 23 | 3 RR | 22 r | 0.305 | 12 | 155 | 10.0 | 45° – 76° |

Acrylic blankets

| width (mm) | foundation | wire | diameter (mm) | rows | ppsi | total h (mm) | angleS a – B |

|---|---|---|---|---|---|---|---|

| 23 | 4 RR | 25/29 Bc | 0.530/0.380 | 12 | 100 | 10.5 | 40° – 82° |

| 23 | 3 RR | 26/30 Bc | 0.480/0.355 | 12 | 130 | 10.0 | 40° – 82° |

| 23 | 3 RR | 27/31 Bc | 0.430/0.330 | 12 | 145 | 10.0 | 45° – 76° |

| 23 | 3 RR | 28/32 Bc | 0.405/0.305 | 12 | 150 | 10.0 | 45° – 76° |

| 23 | 3 RR | 29/33 Bc | 0.380/0.280 | 12 | 155 | 10.0 | 45° – 76° |

| 23 | 3 RR | 22 R | 0.305 | 12 | 155 | 10.0 | 45° – 76° |

Cotton flannel

| width (mm) | foundation | wire | diameter (mm) | rows | ppsi | total h (mm) | angleS a – B |

|---|---|---|---|---|---|---|---|

| 23 | 4 RR | 26/30 Bc | 0.480/0.355 | 18 | 230 | 10.5 | 40° – 89° |

| 23 | 3 RR | 27/31 Bc | 0.430/0.330 | 18 | 245 | 10.0 | 45° – 82° |

| 23 | 3 RR | 28/32 Bc | 0.405/0.305 | 18 | 260 | 10.0 | 45° – 76° |

| 23 | 3 RR | 29/33 Bc | 0.380/0.280 | 18 | 280 | 10.0 | 45° – 76° |

| 23 | 3 RR | 30/34 Bc | 0.355/0.255 | 18 | 300 | 10.0 | 48° – 76° |

| 20 | 3 RR | 30/34 Bc | 0.355/0.255 | 18 | 380 | 10.0 | 48° – 76° |

Nylon - polyester

| width (mm) | foundation | wire | diameter (mm) | rows | ppsi | total h (mm) | angleS a – B |

|---|---|---|---|---|---|---|---|

| 20 | 5 F | 22 R | 0.305 | 18 | 270 | 11.0 | 55° – 82° |

| 20 | 5 F | 24 R | 0.280 | 18 | 310 | 11.0 | 45° – 82° |

| 20 | 5 F | 22 R | 0.305 | 18 | 310 | 10.7 | 48° – 82° |

| 20 | 5 F | 24 R | 0.280 | 18 | 340 | 10.7 | 45° – 82° |

| 19 | 3 RR | 30/34 BN | 0.355/0.255 | 18 | 380 | 10.5 | 45° – 82° |

Knitted fabrics

| width (mm) | foundation | wire | diameter (mm) | rows | ppsi | total h (mm) | angleS a – B |

|---|---|---|---|---|---|---|---|

| 23 | 3 RR | 24 R | 0.280 | 18 | 300 | 10.5 | 48° – 72° |

| 23 | 3 RR | 30/34 BC | 0.355/0.255 | 18 | 310 | 10.5 | 48° – 72° |

| 23 | 3 RR | 29/33 BC | 0.380/0.280 | 18 | 280 | 10.5 | 48° – 72° |

| 23 | 3 RR | 28/32 BC | 0.405/0.305 | 18 | 280 | 10.5 | 45° – 76° |

| 20 | 3 RR | 22 R | 0.305 | 18 | 280 | 11 | 48° – 76° |

| 20 | 5 F | 24 R | 0.280 | 18 | 300 | 11 | 45° – 76° |

| 20 | 5 F | 20 R | 0.330 | 18 | 260 | 11 | 48° – 80° |

| 20 | 5 F | 22 R | 0.305 | 18 | 280 | 11 | 48° – 80° |

| 20 | 5 F | 24 R | 0.280 | 18 | 300 | 11 | 50° – 80° |

| 20 | 5 F | 22 R | 0.305 | 18 | 240 | 11 | 48° – 80° |

U.S.A. style raising fillet

| width (“ – mm) | foundation | wire | diameter (mm) | rows/ TWILL | ppsi | total h (mm) | angleS a – B |

|---|---|---|---|---|---|---|---|

| ¾ – 19 | 3 RR | 28/32 | 0.405/0.305 | 2 / 3 | 220 | 11.5 | 45° – 80° |

| ¾ – 19 | 3 RR | 30/34 | 0.355/0.255 | 3 / 3 | 360 | 11.5 | 45° – 80° |

| ¾ – 19 | 3 RR | 30 | 0.355 | 3 / 3 | 260 | 11.5 | 90° – 0° |

| ¾ – 19 | 3 RR | 28/32 | 0.405/0.305 | 3 / 3 | 280 | 11.5 | 45° – 80° |

| ¾ – 19 | 3 RR | 26/30 | 0.480/0.355 | 3 / 3 | 280 | 11.5 | 45° – 80° |

| ¾ – 19 | 3 RR | 27/31 | 0.430/0.330 | 3 / 3 | 280 | 11.5 | 45° – 80° |

STANDARD FOUNDATION 3 and 4 PLY Red Rubber face 1 mm & white backing cloth

OPEN SET 2 rows / 3 twill

CLOSE SET 3 rows / 3 twill

Brushes for raising fillets on napping machines

| width (“ – mm) | foundation | wire | diameter (mm) | rows/ TWILL | ppsi | total h (” – mm) | angleS a – B |

|---|---|---|---|---|---|---|---|

| 1 ½ – 38 | 3 RR | 30 | 0.355 | 4 / 3 | 100 | 1 ⅛ – 28.5 | 45° – 80° |

| 1 ½ – 38 | 4 RR | 28 | 0.405 | 4 / 3 | 100 | 1 ⅛ – 28.5 | 45° – 80° |

| 1 ½ – 38 | 4 RR | 28 | 0.405 | 4 / 3 | 100 | 1 ¼ – 32.0 | 90° – 0° |

Brushes sheets available on 4-5 RR or 4-5 Felt, all sizes.

Far East style raising fillet

| type | width (mm) | foundation | wire | diameter (mm) | rows/ TWILL | ppsi | total h (mm) | angleS a – B |

|---|---|---|---|---|---|---|---|---|

| B 1 | 23 | 3 RR | 27/31 | 0.430/0.330 | 18 | 310 | 9.5 | 45° – 82° |

| B 2 | 23 | 3 RR | 27/31 | 0.430/0.330 | 18 | 310 | 10.0 | 40° – 89° |

| B 3 | 23 | 3 RR | 28/32 | 0.405/0.305 | 18 | 330 | 9.5 | 48° – 72° |

| B 4 | 23 | 3 RR | 30 | 0.355 | 18 | 260 | 11.0 | 80° – 10° |

| B 5 | 23 | 5 F | 33 | 0.280 | 18 | 260 | 11.5 | 65° – 80° |

| B 6 | 23 | 5 F | 31 | 0.330 | 18 | 280 | 11.5 | 45° – 85° |

| B 15 | 23 | 3 RR | 28/32 | 0.405/0.305 | 18 | 360 | 9.5 | 48° – 72° |

Brushes

| type | width (mm) | foundation | wire | diameter (mm) | ppsi | total h (mm) | angleS a – B |

|---|---|---|---|---|---|---|---|

| TIGER | 26 | 6 VULC | 27/31 | 0.430/0.330 | 310 | 30.5 | 85° – 5° |