Metallic card clothing

Metallic card clothing

The application of metallic card clothing onto spinning carding machines has no limits and is used in the production of low, medium and high quality yarns:

- woollen

- worsted

- semi-worsted

- non-woven

- cotton.

Since there are numerous solutions available for every spinning process, we always ask our customers for the following information in order to accurately determine the type of card clothing to use:

- material to be processed;

- microns;

- fibers type and staple

- length in mm;

- deniers.

For cotton carding it is also necessary to know:

- production in kilos per hour;

- cylinder/doffer speed;

and the technical data concerning the machinery:

- working width;

- rollers diameter.

Once supplied with this information we can suggest the best combination of metallic wire for any type of fiber to be processed, thanks to the research and experience we have acquired in carding over the years.

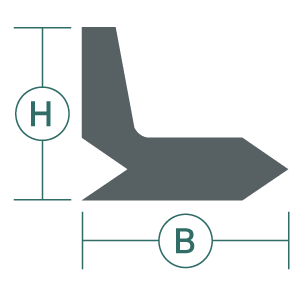

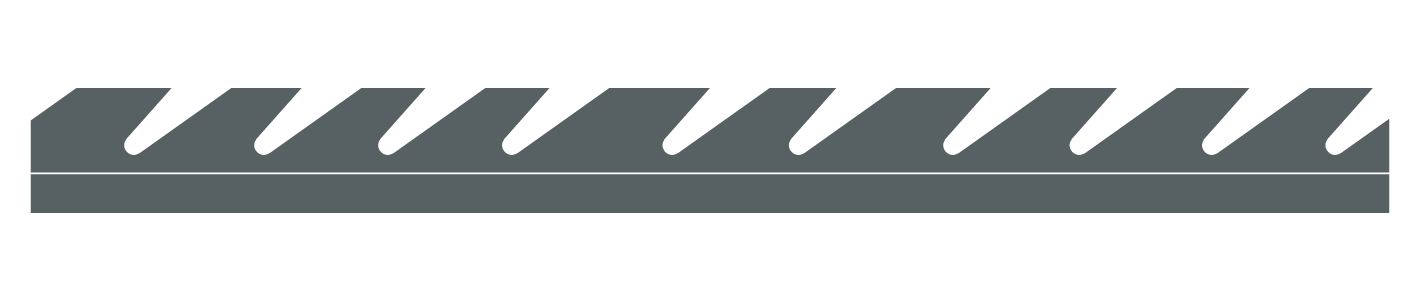

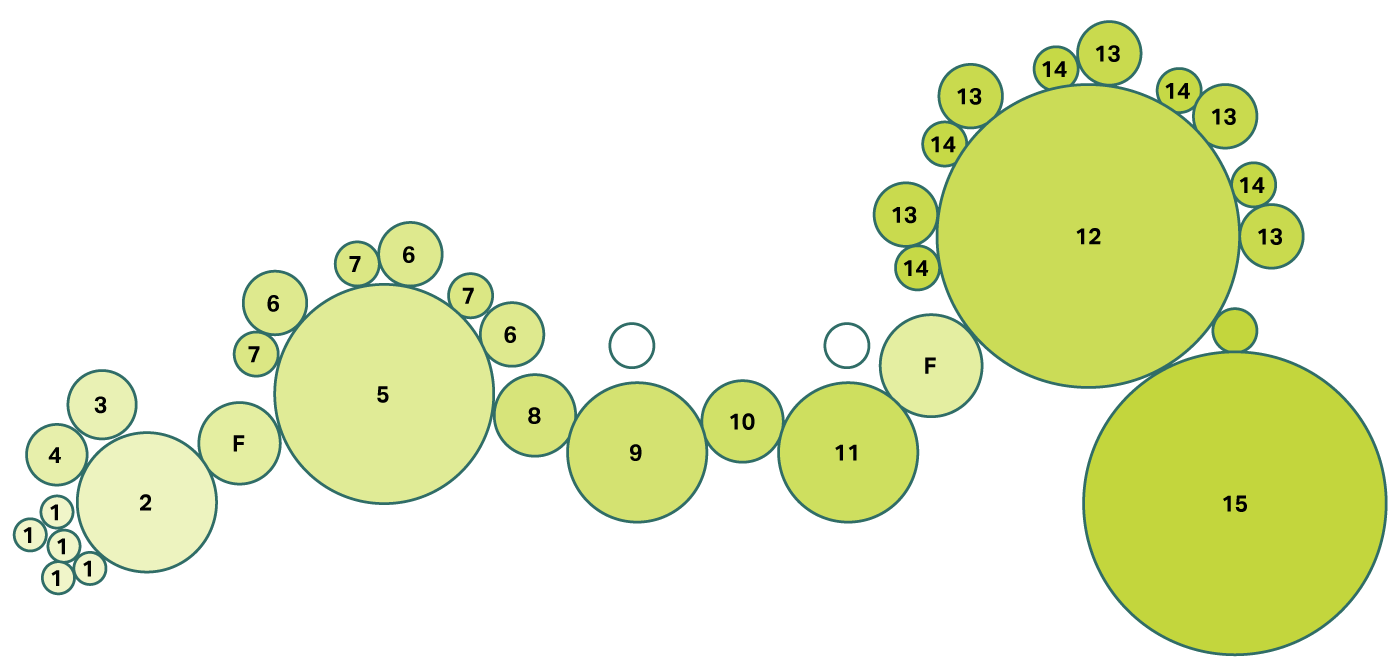

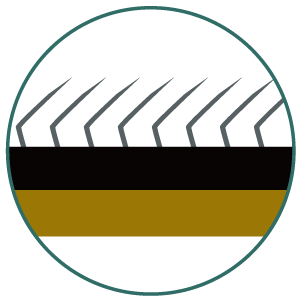

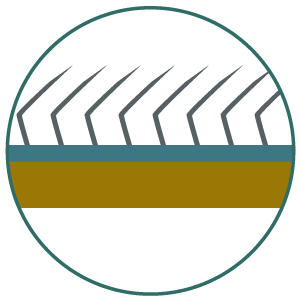

Interlocking wire

Interlocking wire can be used successfully for various types of processing which require particular force in opening and breaking up the fibers, which usually occurs in the avantrain of the woollen carding machines and in Garnett machines. Interlocking metallic wire is the best solution in these cases and thanks to its “V” form it guarantees higher resistance without causing breakage or damage to the machine itself during processing.

A selection of interlocking metallic wire can be found in this page.

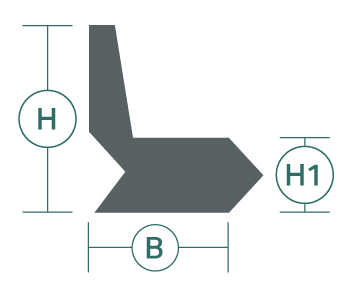

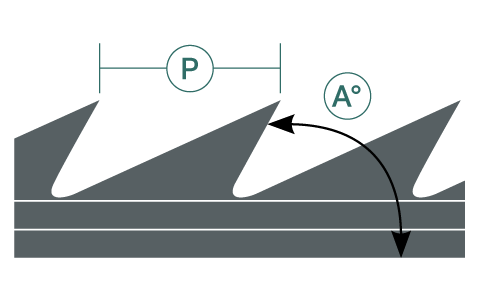

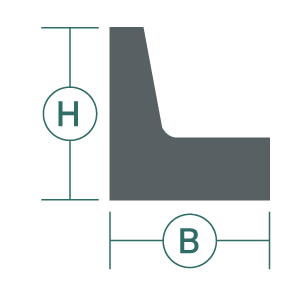

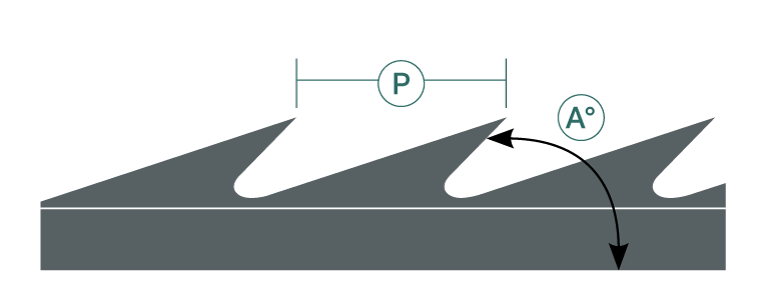

Table's legend

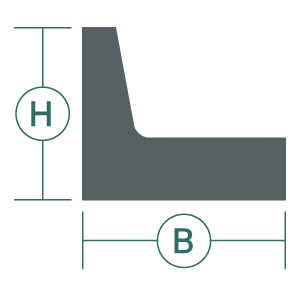

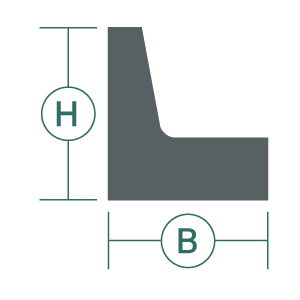

B base

H height

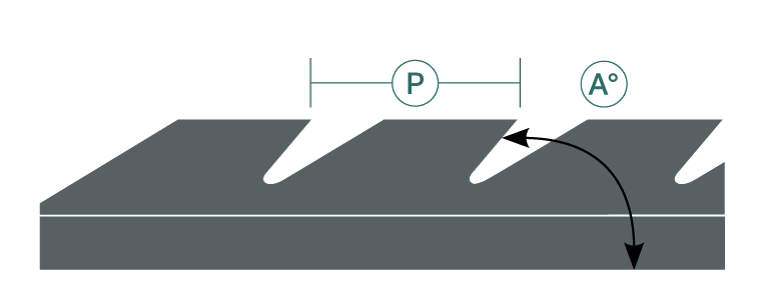

P pitch

A° angle

PPSI points/square inch

FR feed rollers

L lickerin

T transfer

C cylinder

W workers

S stripper

D doffer

ST H1 2.2 mm

| TYPE | B | H | P | A° | PPSI | FR | L | T | C | W | S | D |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| V 6 | 4.20 | 7.5 | 8.5 | 60° | 18 | • | • | • | • | • | • | • |

| V 6 | 4.20 | 6.0 | 8.5 | 65° | 18 | • | • | • | • | • | • | |

| V 8 | 3.18 | 7.5 | 7.5 | 55° | 27 | • | • | • | • | |||

| V 8 | 3.18 | 6.0 | 6.5 | 60° | 31 | • | • | • | • | • | ||

| V 8 | 3.18 | 6.0 | 5.5 | 70° | 36 | • | • | • | • | |||

| V 10 | 2.50 | 6.0 | 7.0 | 70° | 36 | • | • | • | • | |||

| V 10 | 2.50 | 5.2 | 5.0 | 55° | 50 | • | • | • | ||||

| V 10 | 2.50 | 5.5 | 5.0 | 60° | 50 | • | • | • | • | • | ||

| V 10 | 2.50 | 6.0 | 6.5 | 80° | 39 | • | • | |||||

| V 12 | 2.10 | 5.0 | 5.0 | 65° | 60 | • | • | • | • | • | ||

| V 12 | 2.10 | 5.0 | 5.0 | 75° | 60 | • | • | |||||

| V 14 | 1.80 | 5.0 | 4.2 | 70° | 84 | • | • | |||||

| V 14 | 1.80 | 6.5HL | 5.0 | 50° | 70 | • | • | |||||

| V 16 | 1.60 | 5.0 | 5.0 | 55° | 80 | • | • | |||||

| V 16 | 1.60 | 5.0 | 4.5 | 85° | 90 | • | • | |||||

| V 18 | 1.40 | 6.0HL | 4.0 | 50° | 113 | • | • | |||||

| V 20 | 1.30 | 5.0 | 5.0 | 60° | 102 | • | • | • | ||||

| V 20 | 1.30 | 5.0 | 3.6 | 75° | 141 | • | • |

LW H1 1.5 mm

| TYPE | B | H | P | A° | PPSI | FR | L | T | C | W | S | D |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| V 8 | 3.18 | 5.0 | 8.5 | 65° | 24 | • | • | • | • | • | • | |

| V 12 | 2.10 | 4.5 | 5.0 | 70° | 61 | • | • | |||||

| V 16 | 1.60 | 4.5 | 4.2 | 75° | 96 | • | • | |||||

| V 16 | 1.60 | 4.5 | 3.6 | 60° | 113 | • | • | • | ||||

| V 20 | 1.30 | 5.5HL | 4.0 | 50° | 127 | • | • | |||||

| V 20 | 1.30 | 4.0 | 3.0 | 70° | 170 | • | • | |||||

| V 24 | 1.05 | 4.5 | 4.2 | 65° | 145 | • | • | • | ||||

| V 24 | 1.05 | 4.0 | 2.5 | 70° | 244 | • | • | |||||

| V 24 | 1.05 | 5.5HL | 4.0 | 50° | 152 | • | • | |||||

| V 28 | 0.90 | 3.5 | 3.2 | 80° | 224 | • | ||||||

| V 28 | 0.90 | 4.5 | 2.8 | 55° | 254 | • | • |

interlocking wire

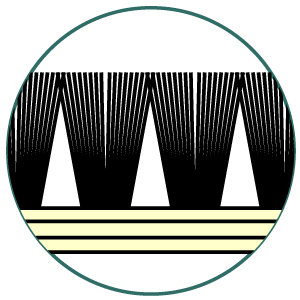

grooved wire

metallic surface wire

Advantages

- Its "V" shape ensures that the wire remains wound onto its roller without breaking or damaging the adjacent rollers.

- Mounting of the interlocking wire is extremely simple and is carried out in the same way as with ordinary M.C.C. A guide that fits into the "V" form applies pressure during mounting and ensures perfect results.

- If roller grooves are present, interlocking wire can be mounted by fixing it with edge wire.

Metallic wire for worsted

S type

V type

S-V type

L type

M type

L-M type

variable random pitch

| TYPE | B | H | P | A° | PPSI | FR | L |

|---|---|---|---|---|---|---|---|

| feed rollers | v 6 | 4.2 | 6.0 | 8.5 | 70° | 18 | |

| lickerin | l 43 l 43 l 43 var l 33 l 33 l 33 var | 4.0 4.0 4.0 3.0 3.0 3.0 | 3.0 | 6.0 8.6 var 6.0 8.6 var | 50° | 19 27 23 25 36 31 | |

| lickerin worker | v 10 l 6 | 2.5 | 5.0 | 4.2 | 50° | 62 | |

| lickerin stripper | v 8 l 6 black brush | 3.15 2.15 – | 5.5 5.0 – | 6.5 8.5 – | 50° 50° – | 31 31 – | |

| first cylinder | v 10 l 33 | 2.5 3.0 | 5.0 3.0 | var | 50° | 35 | |

| first worker | v 10 l 6 | 2.5 | 5.0 | 4.2 | 50° | 62 | |

| first stripper | v 10 l 6 | 2.5 | 5.0 | 4.2 | 50° | 62 | |

| 1st morel brush | tampico | – | – | – | – | – | |

| 1st morel | m 1.0 / 3.8 m 1.0 / 5.5 m 1.0 var | 1.0 1.0 1.0 | 3.6 | 3.8 5.5 var | 50° | 169 117 143 | |

| 2nd morel brush | TAMPICO | – | – | – | – | – | |

| 2nd morel | m 0.8 / 3.8 m 0.8 / 5.5 m 0.8 var | 0.8 0.8 0.8 | 3.6 | 3.8 5.5 var | 50° | 212 146 179 | |

| main cylinder | 501 504 cyl 400 | 0.9 | 3.2 | 3.2 3.2 1.8 | 80° 70° 70° | 224 224 398 | |

| worker | l 9 | 1.0 | 5.0 | 3.0 | 60° | 211 | |

| stripper | v 16 | 1.6 | 4.0 | 4.0 | 90° | 102 | |

| doffer | l 10 pps 0.8 pps 0.9 | 1.0 0.8 0.9 | 5.0 4.0 4.0 | 3.1 2.5 2.5 | 50° 55° 55° | 219 325 298 | |

| transfer | flexible wire | – | – | – | – | – |

Flexible wires

Flexible wire for transfer

Nr. 20 / 24 BIC – Nr. 21 / 25 BIC – Nr. 23 / 27 BIC

FOUNDATION Rubber Felt 4.00 mm 7 – 9 PLY

Flexible wire for workers and strippers

FOUNDATION Vulc rubber 1.0 mm 5 – 7 PLY

Brushes

Black brush

WIDTH 35 mm

HEIGHT 22.5 mm

Tampico

WIDTH 45 mm

HEIGHT 31 mm