Flexible card clothing

Flexible card clothing

Since 1879 BIOTTI card clothing has specialized in the production of flexible card clothing for woollen and worsted carding machines.

With the constant modernization and updating of our plant and production techniques, we have become leaders in the manufacturing of high quality card clothing, which is now sold and appreciated by customers all over the world.

Thanks to years of experience we can offer first-rate and reliable products, as well as technical assistance in choosing and mounting the various types of card clothing onto our client’s machinery.

The choice of flexible card clothing depends on a number of factors and to obtain optimum spinning results we always ask our customers what type of material is to be introduced into the carding machine and the resulting NM.

Once supplied with this information and a diagram or detailed description of the machine, we can then suggest the best combination of foundation and steel-wire necessary to produce the most efficient carding.

Since the choice of card clothing depends on so many different factors, we don’t rely on standardized charts but examine every individual case, so as to determine the best possible technical solution to fit each customers needs.

Foundations

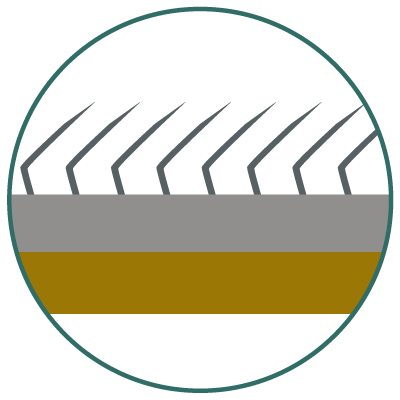

felt

card clothing

FELT 4.50 mm 7 – 9 – 11 PLY

FELT 3.00 mm 5 – 6 – 7 PLY

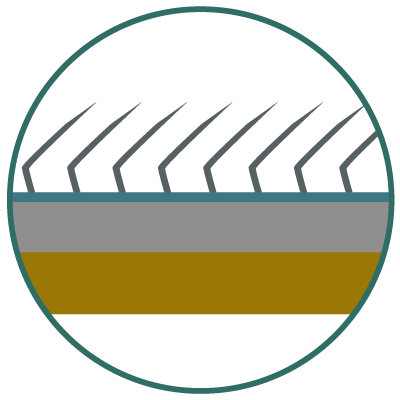

felt/vulc

card clothing

FV 4.50 mm 7 – 9 PLY

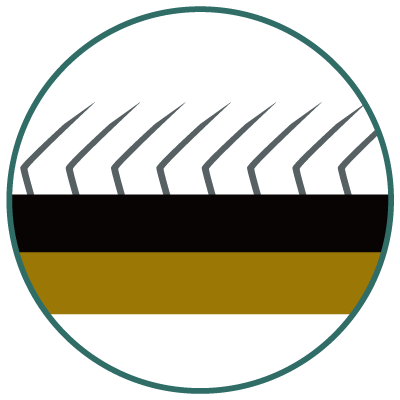

rubber felt

card clothing

RF 4.00 mm 7 – 9 – 11 PLY

Other names for

RF Card Clothing:

OPCR (Oil Proof Cushion Rubber)

CF (Cushion Felt)

BCR (Black Cushion Rubber)

vulc card

clothing

VULC rubber 1.00 mm

5 – 6 – 7 – 8 – 9 PLY

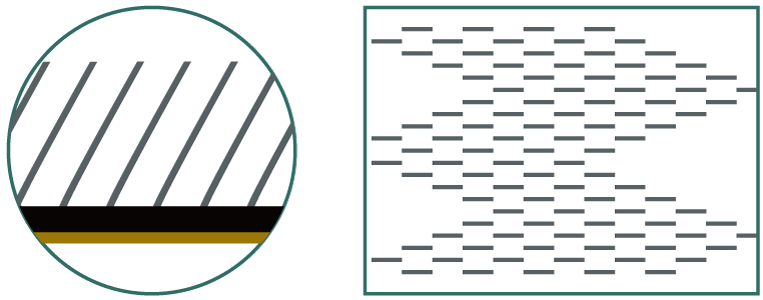

Fancy fillet

foundation soft sponge 3.00 mm 5-6 PLY

SETTING diagonal

WIDTH 38-39/46-48 mm

HEIGHT 25 mm

SETTING special ZZ

WIDTH 46 mm

HEIGHT 25 mm

foundation soft sponge 3.00 mm 5-7 PLY

CLEARSTRIP

SETTING 3 x 3

WIDTH 38 mm

HEIGHT 25-28.5-38 mm

LOW BEND

SETTING 3 x 3

WIDTH 38 mm

HEIGHT 25-28.5-31.5 mm

Mainly used steel wires

bright hardened and tempered wire • tinned-nickeled wire • stainless steel wire

| ENGLISH | continental | ROUND (mm) | NUMBER | BICONVEX (mm) |

|---|---|---|---|---|

| 21 | 0 | 0.810 | 17/21 | 1.420 – 0.810 |

| 22 | 2 | 0.710 | 18/22 | 1.215 – 0.710 |

| 23 | 4 | 0.630 | 19/23 | 1.015 – 0.630 |

| 24 | 6 | 0.580 | 20/24 | 0.910 – 0.580 |

| 25 | 8 | 0.530 | 21/25 | 0.810 – 0.530 |

| 26 | 10 | 0.480 | 22/26 | 0.710 – 0.480 |

| 27 | 12 | 0.430 | 23/27 | 0.630 – 0.430 |

| 28 | 14 | 0.405 | 24/28 | 0.580 – 0.405 |

| 29 | 16 | 0.380 | 25/29 | 0.530 – 0.380 |

| 30 | 18 | 0.355 | 26/30 | 0.480 – 0.355 |

| 31 | 20 | 0.330 | 27/31 | 0.430 – 0.330 |

| 32 | 22 | 0.305 | 28/32 | 0.405 – 0.305 |

| 33 | 24 | 0.280 | 29/33 | 0.380 – 0.280 |

| 34 | 26 | 0.255 | 30/34 | 0.355 – 0.255 |

| 35 | 28 | 0.230 | 31/35 | 0.330 – 0.230 |

| 36 | 30 | 0.205 | 32/36 | 0.305 – 0.205 |

PPSI

bright hardened and tempered wire • tinned-nickeled wire • stainless steel wire

| CONTINENTAL WIRE | PPSI |

|---|---|

| 6 | 140 |

| 8 | 180 |

| 10 | 205 |

| 12 | 230 |

| 14 | 270 |

| 16 | 310 |

| 18 | 335 |

| 20 | 385 |

| 22 | 425 |

| 24 | 475 |

| 26 | 535 |

| 28 | 600 |

| 30 | 670 |

| UK STYLE | PPSI |

|---|---|

| 10/26 | 240 |

| 12/27 | 300 |

| 14/28 | 320 |

| 16/29 | 340 |

| 18/30 | 420 |

| 20/31 | 460 |

| 22/32 | 500 |

| 24/33 | 580 |

| 26/34 | 660 |

| 28/35 | 800 |

| BICONVEX WIRE | PPSI |

|---|---|

| 20/24 | 105 |

| 21/25 | 140 |

| 22/26 | 170 |

| 23/27 | 195 |

| 24/28 | 230 |

| 25/29 | 260 |

| 26/30 | 285 |

| 27/31 | 325 |

| 28/32 | 360 |

| 29/33 | 400 |

| 30/34 | 450 |

Finishing

side grinding

extra hardened points

polished points

Flexible card clothing standard width

| CONTINENTAL (mm) | UK AND U.S.A. STYLE (mm – “) | ||

|---|---|---|---|

| Cylinder | 50 – 60 – 70 | 57 – 51 | 2 ¼ – 2 |

| Doffer | 56 – 60 | 57 – 51 | 2 ¼ – 2 |

| Workers | 45 – 50 | 38 | 1 ½ |

| Stripper | 30 – 35 | 25.4 | 1 |

| Transfer | 51 | 38 | 1 ½ |

| Fancy | 38 – 46 | 38 | 1 ½ |

| Doffer cleaner | 40 | 38 | 1 ½ |

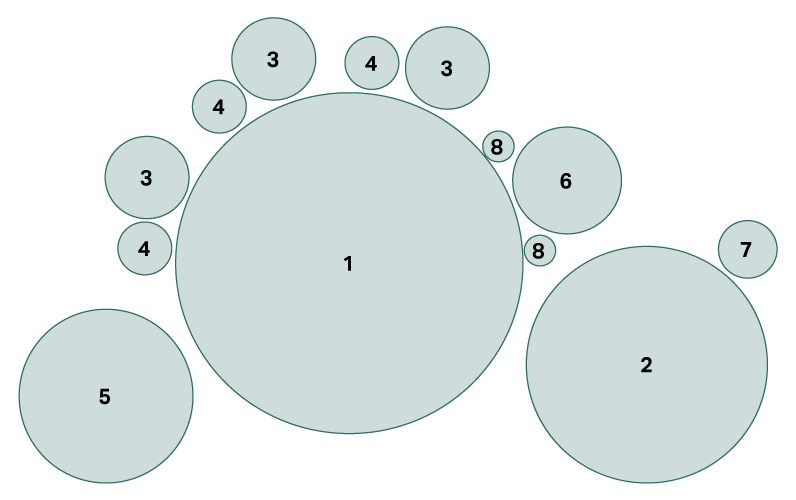

Width of flexible card clothing and foundation can be determined by working width of woollen carding machine and diameters of rollers to be covered.

1 – CYLINDER 2 – DOFFER 3 – WORKERS 4 – STRIPPER 5 – TRANSFER 6 – FANCY 7 – DOFFER CLEANER 8 – FLY STRIPPER

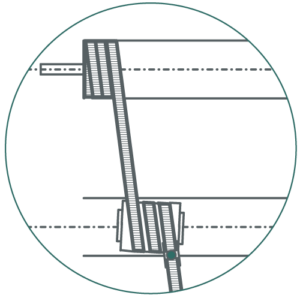

Flexible card clothing suggested tensions

7 PLY RF 60 mm 3.8×60 = Kg

| FOUNDATION | PLY | KG/MM … WIDTH |

|---|---|---|

| FANCY SS / RF 3.00 mm | 5 | 2.8 |

| FANCY SS / RF 3.00 mm | 7 | 3.0 |

| RF / CF / OPCR 4.00 mm | 7 | 3.8 |

| RF / CF / OPCR 4.00 mm | 9 | 4.6 |

| RF / CF / OPCR 4.00 mm | 11 | 5.4 |

| FELT 3.00 mm | 5 | 3.0 |

| FELT 3.00 mm | 7 | 3.4 |

| FELT 4.50 mm | 7 | 3.6 |

| FELT 4.50 mm | 9 | 4.4 |

| FELT 4.50 mm | 11 | 5.2 |

| VULC 1.00 mm | 5 | 2.7 |

| VULC 1.00 mm | 6 | 2.9 |

| VULC 1.00 mm | 7 | 3.1 |

| VULC 1.00 mm | 8 | 3.3 |

| VULC 1.00 mm | 9 | 3.5 |